Water treatment in industry: optimizing a very precious resource

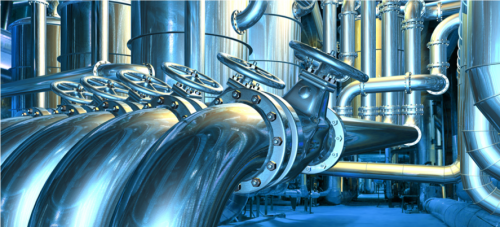

Water is the most important fluid for life, and there is no living being that can survive without it. However, water treatment is also essential for the industry as a whole. From cooling systems to hydroelectric generation processes, concentrators, evaporators, reactors, etc., all of them require water (in its various states) to perform their function correctly. In Lidering, we discuss the water treatment process and how to optimize the use of water resources, which require specific solutions to ensure water efficiency. Industrial challenges using water as the primary fluid There are many industrial sectors dedicated to water treatment in order…